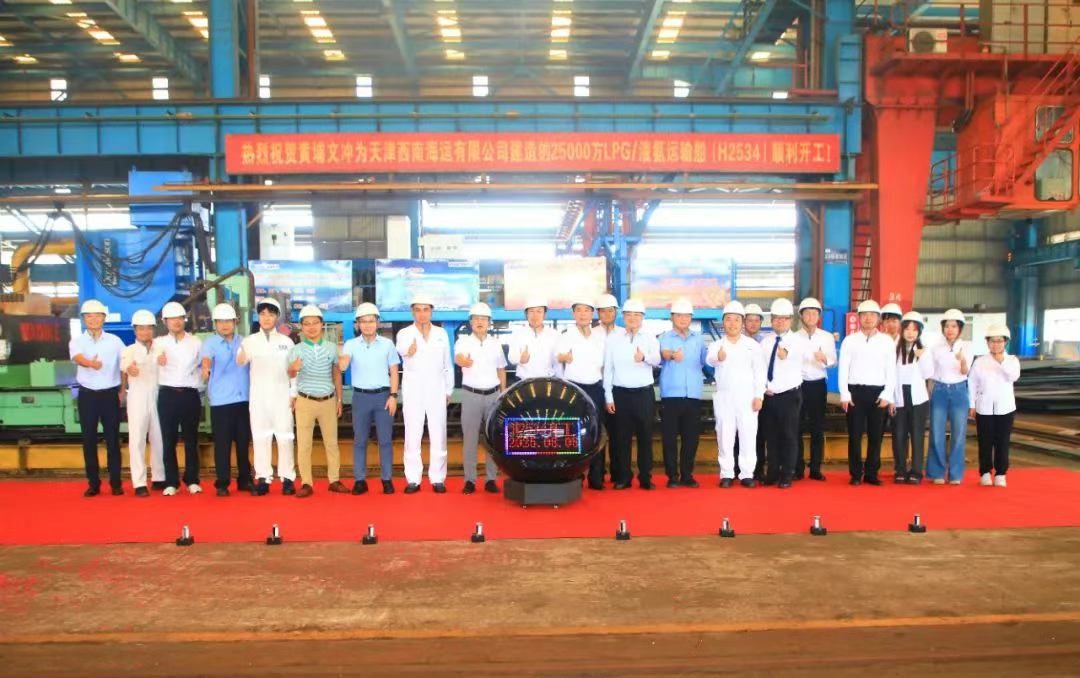

On August 8th, Huangpu Wenchong Shipbuilding and China’s Tianjin Southwest Maritime joined hands again, and together with China Classification Society and other relevant units, held a steel cutting ceremony for the second 25,000 cbm ammonia dual-fuel LPG/liquid ammonia carrier (Hull No.H2534).

This vessel inherits the outstanding performance and cutting-edge design of first vessel in the series. The smooth commencement of construction of this vessel marks that the series of projects has steadily moved from the technical breakthrough stage of the first vessel to the stage of rapid production.

Since the commencement of construction of the first vessel in June, Huangpu Wenchong Shipbuilding has leveraged its extensive technical expertise and lean management experience in the small and medium-sized gas carrier sector to efficiently advance the entire process, from design optimization to material procurement and production organization.

The technical team completed the standardization of the drawings for the series of vessels. The production department, drawing on the experience gained from the first vessel, developed a modular construction plan in advance. The supply chain teamed up with core suppliers to establish a dedicated guarantee mechanism to ensure that key equipment, such as the ammonia fuel system, was delivered on schedule.

Currently, all aspects of the project’s design and production are progressing smoothly, laying a solid foundation for efficiency and quality assurance for the subsequent batch production of vessels.

It is worth mentioning that on the morning of the same day, Huangpu Wenchong Shipbuilding officially delivered the first 1250TEU methanol dual-fuel open container vessel built for Singapore’s X-Press Feeder Group.

The 1250TEU vessel delivered this time is another demonstration project of Huangpu Wenchong in practicing the green and low-carbon concept.

The vessel integrates over 40 new technologies, including a methanol fuel tank, a methanol dual-fuel main engine, a shaft-mounted generator system and a CPP propulsion system. Its equipment interfaces are among the most complex in the industry. Through independent research and development, Huangpu Wenchong has achieved breakthroughs in key technologies, including methanol medium material sealing and fuel supply system safety control, laying the foundation for subsequent ships.

Compared with LNG fuel, the carbon emission factor of the vessel’s methanol fuel is only 1.375, half of LNG (2.75), and has the dual advantages of economy and environmental protection. At the same time, it can be stored in liquid form at room temperature and pressure, without the need for LNG’s low-temperature and high-pressure system, and the modification and maintenance costs are lower, further increasing its attractiveness as a marine fuel.