Over the past few days, Southeast Shipyard, a subsidiary of Fujian Shipbuilding Industry Group Corporation (Fujian Shipbuilding), has successively completed 8 production milestones within three days, including the launching of 3 vessels, the keel-laying of 2 vessels, the moving of 2 vessels onto the building berth, and the triumphant return of 1 vessel from sea trials.

Two 5,000-horsepower new energy tugboats launched at Xiamen Port

On September 10 and 11, Southeast Shipyard successfully launched two 5,000-horsepower new energy tugs (DN643-1/2) for Xiamen Port Holding Group.

The tugboats were independently developed by Fujian Shipbuilding Research and Design Institute. It has a total length of 38.30 meters, a beam of 10.60 meters, a battery pack capacity of approximately 7,300 kWh, and a cruising range of no less than 8 hours at a still water speed of 8 knots. It can meet intelligent energy efficiency requirements and provide auxiliary decision-making and suggestions for ship energy efficiency management.

This tugboat meets the operational requirements of coastal port areas, is suitable for coastal navigation, and assists container ships, bulk carriers, and other vessels in berthing and unberthing operations within port areas, as well as in docking and undocking operations. It is classified by the China Classification Society.

This project actively responds to the Fujian Provincial Party Committee and Provincial Government’s call for “Electric Fujian” and green, low-carbon development. It represents a concrete implementation of the national “dual carbon” strategy and fully demonstrates Fujian Shipbuilding’s exemplary and leading role in the field of electric vessels.

18,500 DWT Oil and Chemical Tanker Launched

On September 12, Southeast Shipyard successfully launched an 18,500 DWT oil/chemical tanker (MW516-6).

This vessel has an overall length of 149.8 meters and a beam of 22.8 meters. Its primary cargoes include crude oil, petroleum products with a density below 1.54 tons per cubic meter, chemicals (Class II and III), liquid chemicals, and IMO Category II and III petroleum products listed in MARPOL Annex I and the IBC Code. The main engine and generator sets are equipped with Selective Catalytic Reduction (SCR) systems for nitrogen oxide emission control, meeting IMO Tier III requirements and ICE CLASS 1C ice-strengthened standards.

This type of vessel adopts a multi-load line design to meet the requirements of different ship flag countries and ports; the liquid cargo system can unload six groups of liquid cargoes at the same time; the propulsion system adopts a low-speed two-stroke diesel engine, equipped with an adjustable pitch propeller and a front energy-saving guide wheel device, and is also equipped with a variable frequency shaft generator set, which can realize the function of operating without a generator set during navigation, thereby reducing its energy consumption while improving maneuverability.

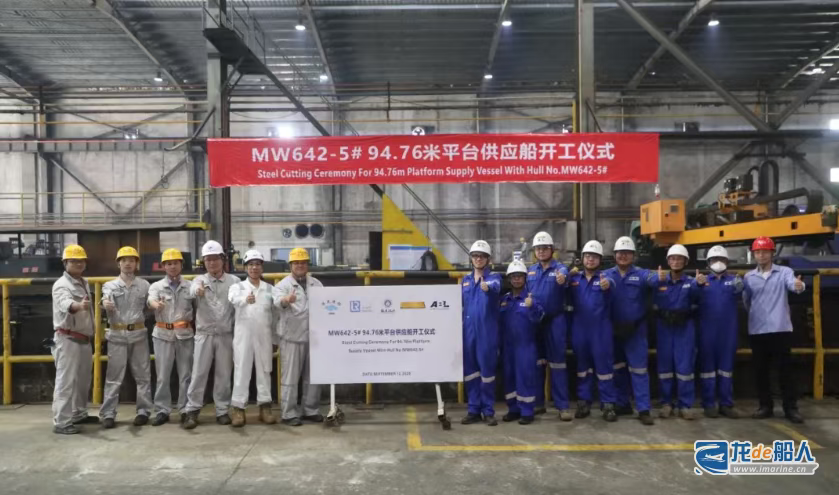

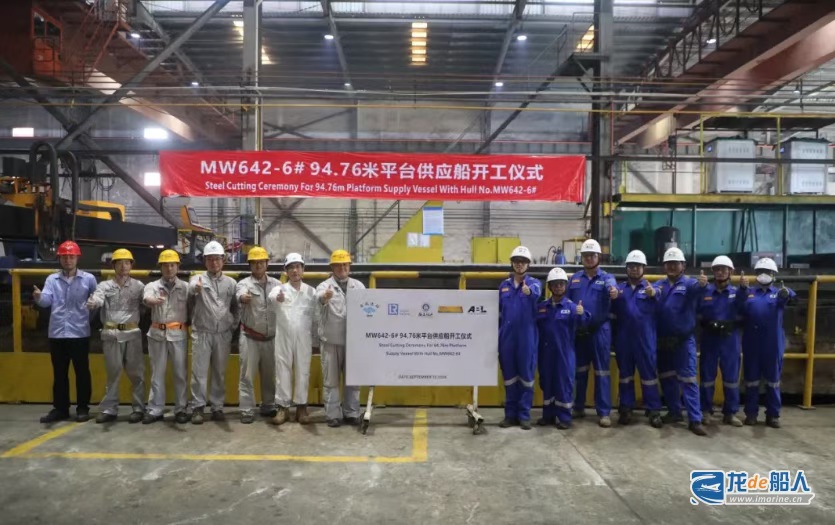

Construction of two 94.76-meter platform supply vessels commenced

This type of vessel has a total length of 94.76 meters, a beam of 19 meters, and a structural draft of 6.5 meters. It adopts a brand-new electric propulsion system, with four 2200KW diesel generator sets providing power and electricity for the entire vessel. Two 2150KW fixed-pitch fully-rotating rudder propellers, two 1250KW tunnel-type bow thrusters, and one 1000KW fully-rotating telescopic bow thruster provide propulsion and positioning power for the entire ship. It is classified by LR classification society and meets the requirements of DP(AA), ECO, CAC3, GR(ML, A) and other classification notations.

This vessel is mainly used for the transportation of industrial personnel and materials to and from offshore drilling platforms. It can carry fresh water, fuel oil, cement, mud, drilling water, crude oil, methanol, materials and equipment, etc. It is also capable of providing fire-fighting services and personnel rescue for other offshore ships or offshore facilities. Meanwhile, it reserves space for the future installation of ROV/DSV (Remotely Operated Vehicle/Dive Support Vessel), offshore cranes, helicopter platforms, moon pools and other equipment. It is an advanced, energy-saving and environment-friendly electric propulsion multi-purpose platform supply vessel.

18,500 DWT Oil/Chemical Tanker Completes Successful Sea Trials

On September 10, the 18,500 DWT oil/chemical tanker (DN517-3) built by Southeast Shipyard successfully completed its sea trials.

During sea trials, the project team completed a series of tests on the main engine, steering gear, thrusters, and vessel performance. All measured data met design specifications, earning high praise from the shipowner and classification society. Next, the team will focus on implementing corrective actions based on trial feedback to ensure the vessel is delivered on schedule and to the highest quality standards.

Two 88-meter multi-purpose platform supply vessels laid keel

On September 10, two 88-meter multi-purpose platform supply vessels were laid keel at Southeast Shipyard.