Recently, Fujian Shipbuilding Industry Group Corporation’s (Fujian Shipbuilding) shipyards have achieved two major production milestones in succession.

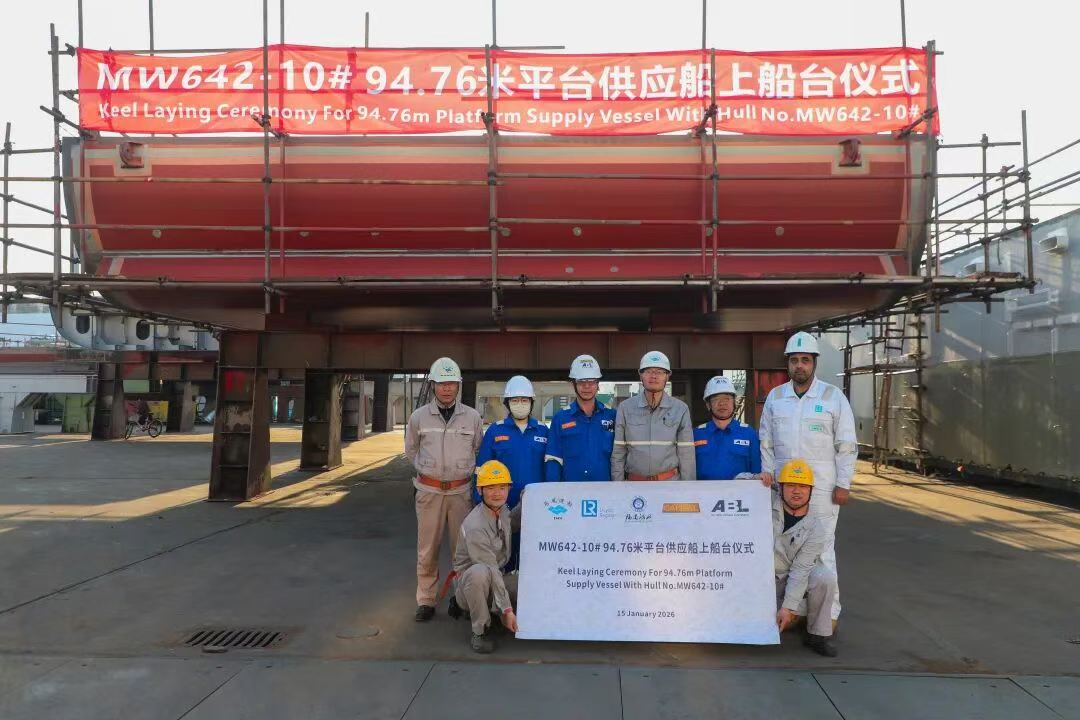

On January 15, the 94.76-meter platform supply vessel (MW642-10) built by Fujian Shipbuilding’s Mawei Shipyard was successfully laid keel.

This vessel has an overall length of 94.76 meters, a beam of 19 meters, and a structural draft of 6.5 meters. It adopts a brand-new electric propulsion system, with 4 sets of 2,200 kW diesel generator sets supplying power and electricity for the entire vessel. Propulsion and positioning power are provided by 2 sets of 2,150 kW fixed-pitch azimuth thrusters, 2 sets of 1,250 kW tunnel bow thrusters, and 1 set of 1,000 kW azimuth retractable bow thruster. Classified by Lloyd’s Register (LR), the vessel meets the requirements for class notations including DP(AA), ECO, CAC3, and GR(ML, A).

This vessel is primarily designed for transferring personnel and supplies to offshore drilling platforms. It can transport freshwater, fuel oil, cement, drilling mud, drilling water, crude oil, methanol, materials, and equipment. Additionally, it provides firefighting and personnel rescue services for other vessels or offshore facilities. The design incorporates provisions for future installation of ROV/DSV systems, offshore cranes, helicopter platforms, and moon pools. It represents an advanced, energy-efficient, environmentally friendly, electric-powered multi-purpose platform supply vessel.

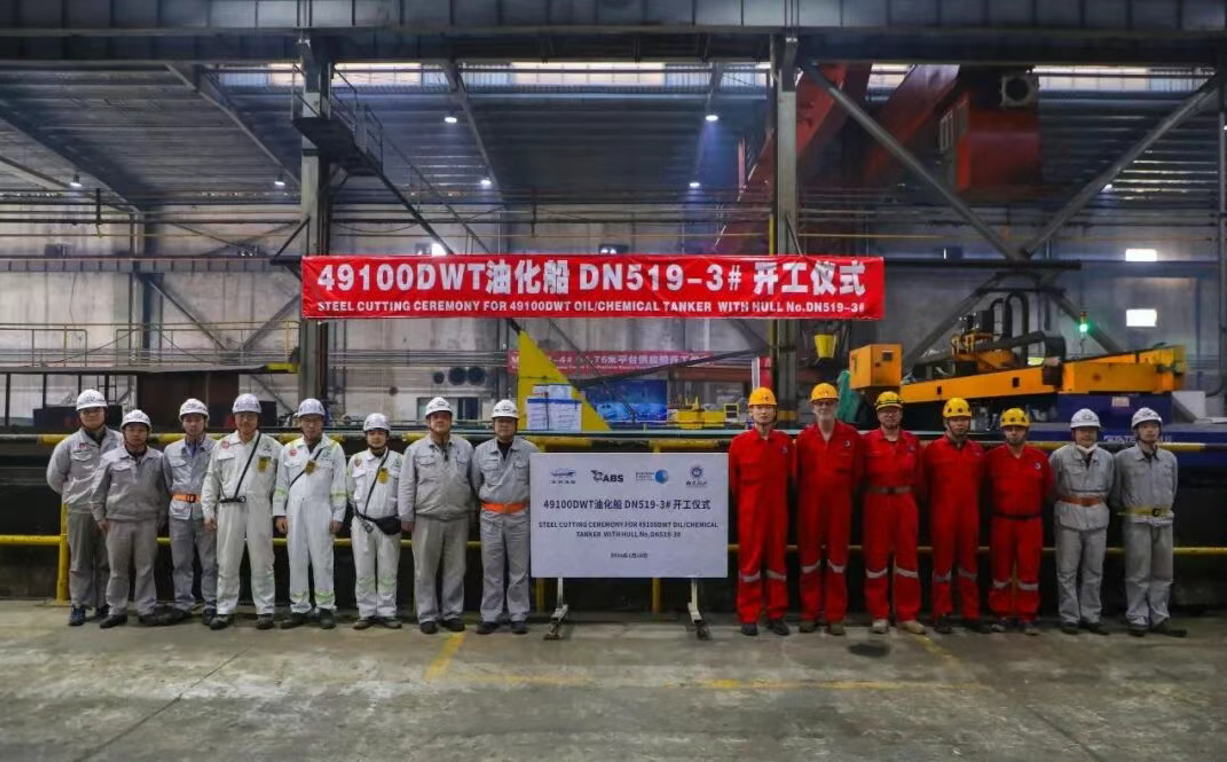

On January 16, Southeast Shipyard, a subsidiary of Fujian Shipbuilding, commenced construction of a 49,100 DWT oil/chemical tanker.

This vessel has an overall length of 182.95 meters, a beam of 32.20 meters, and a structural draft of 13.30 meters. At structural draft, its deadweight tonnage is approximately 49,100 tons. with a design speed of 14.5 knots.

It is primarily designed for transporting refined oil products, vegetable oils, and liquid chemicals (Class II and III) meeting IBC Code requirements with a flash point ≤60°C. Its liquid cargo area features a double bottom and double hull configuration, comprising nine pairs of liquid cargo tanks and one pair of slop tanks, enabling simultaneous loading of up to 10 different cargoes.