JoongAng Ilbo, a major South Korean media outlet, reported that falls, burns, and even fatalities are common in South Korea’s shipbuilding and steel industries. Taking the shipbuilding industry as an example, on May 17, a subcontractor at HD Hyundai Samho fell into a inspection hole while performing installation work (securing panels before welding to ensure proper welding position) and was pronounced dead four days later.

High-risk operations

According to reports, shipbuilding and steel manufacturing are two core manufacturing industries in South Korea. These industries involve high temperature and high-altitude operations (often more than two meters above the ground). Workers need to handle molten metal, heavy steel parts and large machinery, which often leads to frequent accidents.

The mixing of workers from main contractors, subcontractors, and external companies on the same job sites has led to significant variations in safety standards and awareness. Labor shortages have also led companies to rely more on foreign workers with limited Korean language skills.

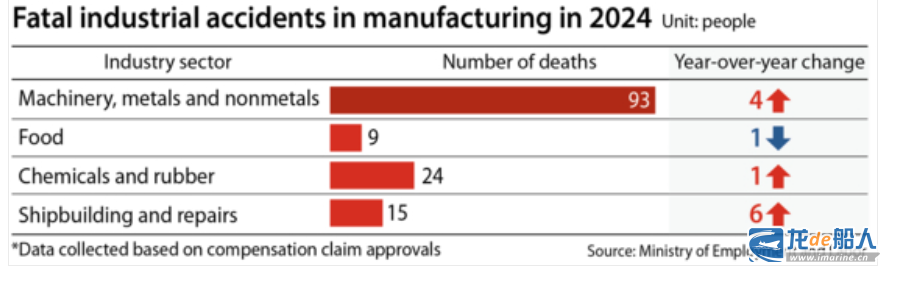

According to data from South Korea’s Ministry of Employment and Labor, 187 workers in South Korea’s manufacturing industry died from industrial accidents in 2024. Among them, the number of fatalities in the shipbuilding industry reached 15, with an accident rate as high as 2.63%—more than three times the average accident rate of 0.8% in the manufacturing industry.

Safety gives way to construction period

In 2024, South Korean shipbuilders ranked second in the total number of new ship orders worldwide. The South Korean industry criticized that enterprises did not put safety first in pursuit of cost reduction and tight delivery schedules.

South Korean industry insiders point out that the shipbuilding industry, which has gained an advantage in trade negotiations between South Korea and the United States thanks to its technological edge, now urgently needs investment to reduce the risk of industrial accidents.

According to data from South Korea’s Ministry of Employment and Labor, between January 2024 and March 2025, a total of 1,139 workers in the shipbuilding industry suffered from accidents or work-related illnesses. Among them, HD Hyundai Heavy Industries recorded 308 accidents, while Hanwha Ocean reported 328 accidents. On average, the two companies experienced at least one accident almost every working day, with their monthly average number of accidents reaching 20.5 and 21.9 respectively.

Some analysts believe that the root cause of frequent accidents in the shipbuilding industry lies in the industry’s low-cost model. In the 1970s and 1980s, South Korean shipbuilding companies quickly seized market share from their competitors, Japanese shipbuilding companies, through their labor cost advantages and faster delivery speeds, thereby achieving rapid development.

However, since the late 2000s, the shipbuilding industry has been in a state of prolonged decline, resulting in a significant reduction in shipbuilders’ investment in safety. At the same time, with the expansion of outsourcing, dependence on foreign and temporary workers has also increased.

It is reported that between February and March 2024, South Korea’s Ministry of Employment and Labor conducted a special inspection at Hanwha Ocean’s Geoje Shipyard. During the inspection, 61 violations were identified, including the lack of guardrails and inadequate fall protection measures. Based on these findings, Hanwha Ocean was fined 26.5 billion won. Hanwha Ocean previously stated, “Before and after the special inspection, the company conducted in-depth reviews together with external experts and is currently implementing improvement measures.”

A senior researcher at the Export-Import Bank of Korea also said, “The older the shipyard facilities are, the more likely they are to lack basic safety equipment.”

Outsourcing leads to frequent fatal accidents

In the shipbuilding industry, tens of thousands of workers are spread across different stages of production, and this type of work model has been criticized for its over-reliance on outsourcing.

According to a 2022 survey by South Korea’s Ministry of Employment and Labor, only about 21.5% of the 51,000 workers in the shipbuilding industry are regular employees, and most high-risk operations are performed by outsourced workers.

A contracted worker from a shipyard revealed to JoongAng Ilbo, “Regular employees are rarely assigned to work at height, such as painting, pipeline installation and external structure construction.” Industry insiders stated that when subcontractors further subcontract projects to “temporary worker teams”—informal daily laborers hired at lower wages—working conditions deteriorate even further.

Currently, under pressure from the government, South Korean shipbuilding enterprises have committed to improving safety measures. HD Hyundai Heavy Industries has implemented a new safety and health management system—The Safe Care—since August 18. This system designates 9 core risk factors, including falls, crushing injuries, electric shocks, suffocation, and fires, as “absolutely prohibited accidents.” It also stipulates that if relevant safety regulations are violated, operations will be immediately halted even if no actual accident occurs, implementing a zero-tolerance principle.

Hanwha Ocean announced in its investment plan released in September 2024 that it plans to invest 1.976 trillion won by 2026 to achieve a zero-accident workplace.

Samsung Heavy Industries has established a Safety Management Department and set up an Occupational Safety and Health Advisory Committee composed of 5 external experts (which holds meetings once a quarter). Additionally, in May this year, the company established an “Integrated Monitoring Center” responsible for safety and security at its Geoje Shipyard.