A bulk carrier veered off course shortly after leaving port and was forced to drop anchor in an emergency after discovering that its rudder was missing… After more than a year of investigation, the NNew Zealand’s Transport Accident Investigation Commission (TAIC) recently released its investigation report on the accident.

On July 24, 2023, the cargo vessel Achilles Bulker departed from Tauranga Port in New Zealand under the guidance of a pilot. Shortly after leaving the port, the bow of the vessel began to veer to the port side, deviating from the planned centerline of the course. While the crew was attempting to correct the course, the rudder blade suddenly broke off, rendering the vessel uncontrollable. The vessel drifted toward shallow waters. Fortunately, through the efforts of the pilot and crew, two anchors were successfully dropped, preventing the vessel from running aground.

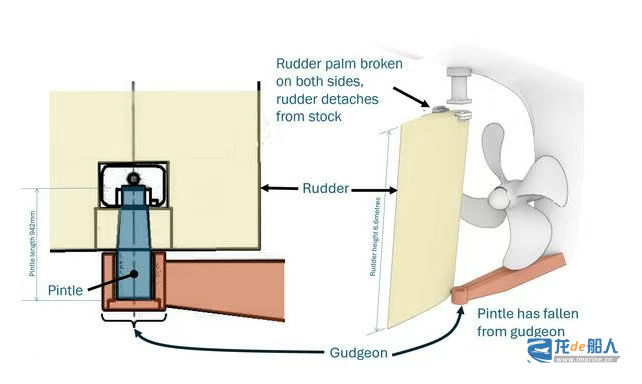

According to the investigation report, the direct cause of the rudder detachment was the loss of the bottom pintle. The pintle is a key component of the rudder system that rotates freely to enable the rudder to turn. TAIC stated that the installation method of the pintle is critical to the durability of the rudder system and to preventing the pintle and rudder from detaching.

The Achilles Bulker is a 32,700 DWT Handy bulk carrier built and delivered by Kanda Shipyard in Japan in October 2003.

In 2021, the “Achilles Bulker” underwent scheduled dry-dock maintenance at a Chinese shipyard. During the process, due to the discovery of wear on the rudder pintle’s brass bushing, the rudder pintle was removed and reinstalled by workers. However, there was a welding quality issue (cold solder joint) with the stopper of the nut used to secure the pintle, which went undetected by both the surveyor and the shipowner.

After the vessel was put back into operation, these poorly welds suffered fatigue fractures due to prolonged vibration, which in turn caused the stopper to fall off. Consequently, the nut used to secure the pintle gradually loosened and eventually failed.

The TAIC report stated that prior to the accident, the pintle had already detached and sunk to the seabed. Without the pintle, the bottom of the rudder lost its support, causing the rudder system to oscillate repeatedly. The rudder root was subjected to excessive lateral loads, resulting in fatigue cracks that eventually led to its fracture, causing the entire rudder to detach.

Regarding this accident, TAIC recommends:

- The Chinese shipyard responsible for dry dock maintenance on the vessel must establish strict pintle installation quality assurance procedures (this recommendation has been communicated to the China Maritime Safety Administration).

- The New Zealand Maritime Association should work with the International Maritime Organization (IMO) to promote higher quality assurance standards for rudder system installation, maintenance, and repair processes globally.

In addition, TAIC stated that shipowners and operators are fully responsible for their vessels and must therefore adequately supervise the repair of critical system components to ensure that repairs are effective. Loss of controllable maneuverability is particularly dangerous when a vessel is navigating in pilotage waters, and pilots and crew members must also be prepared to respond to such incidents.