On December 2-3, at the Shanghai Marintec 2025, the four major classification societies—Lloyd’s Register (LR), Det Norske Veritas (DNV), American Bureau of Shipping (ABS), and Bureau Veritas (BV)—awarded GASA or AiP certificates to six newly developed ship designs from Jiangnan Shipyard.

192,000 m³ Type B LNG Carrier with Electric Propulsion

At the launch ceremony, Jiangnan Shipyard introduced the vessel, and ABS officially issued Jiangnan Shipyard the Approval in Principle (AiP) certificate for the 192,000 m³ Type B electric propulsion LNG carrier.

The vessel utilizes a Type B cargo hold with completely independent intellectual property rights, resulting in a larger capacity than mainstream international LNG carriers of the same size. This design also gives it advantages such as lower overall energy consumption, lower operating and maintenance costs, and higher residual value. The successful launch of this vessel type marks the expansion of Jiangnan Shipyard’s independently developed “Brilliance® II” liquid cargo containment system from VLECs to LNG carriers. This represents a further breakthrough in the research and design of large LNG carriers in China and will provide a “Jiangnan-type solution” for global LNG maritime transportation.

New Generation 175,000 m³ Mark III Flex Membrane LNG Carrier

At this exhibition, BV awarded an AiP certificate to the new-generation 175,000 m³ Mark III Flex membrane LNG carrier independently developed and designed by Jiangnan Shipyard. LR and DNV awarded GASA certificates to this new-generation 175,000 m³ Mark III Flex membrane LNG carrier.

The new-generation 175,000 m³ Mark III Flex membrane-type LNG carrier represents Jiangnan Shipyard’s latest universally applicable, low-carbon, intelligent, and flexible LNG transport solution. Building upon the optimized foundation of previously delivered vessels, it incorporates comprehensive upgrades designed to meet international shipowners’ evolving demands for global LNG trade, low-carbon operations, and smart applications. This solution embodies Jiangnan Shipyard’s independent research and development capabilities.

To meet the diverse operational needs of shipowners, the new generation of vessel designs offers a comprehensive suite of upgrade options, including e-LNG fuel systems, shaft generators, sail-assisted propulsion, carbon capture systems, shore power interfaces, high loading factor configurations, ice-class reinforcement, anti-freezing and de-icing systems, as well as Jiangnan Shipyard’s proprietary intelligent auxiliary systems. Shipowners can flexibly customize efficient, low-carbon, and intelligent vessel configurations tailored to their specific routes and operational scenarios.

103,000 m³ Type B Very Large Ethane Carrier (Triple-Tank Configuration)

ABS has granted an AiP certificate for the 103,000 m³ Type B Very Large Ethane Carrier (three-tank configuration) independently developed and designed by Jiangnan Shipyard.

The core highlight of this vessel is its innovative three-tank configuration, utilizing the independently developed “BrilliancE® II” Type B liquid tank containment system. Within primary dimensional constraints, this design achieves significantly enhanced space utilization, flexibly accommodating the transport of various olefin liquefied gases such as ethane. The triple-tank configuration substantially reduces redundant structures and piping systems, simplifying construction processes and further optimizing the building schedule. Additionally, the vessel incorporates the latest generation Wind Assist Propulsion System (WAPS), projected to reduce annual CO₂ emissions by approximately 1,000 tons, effectively contributing to achieving dual carbon reduction goals.

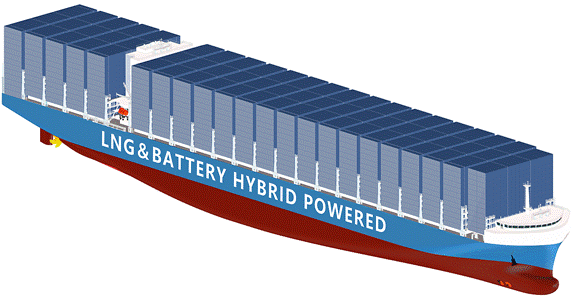

19,000 TEU LNG & Battery Hybrid Container Ship (KUN 19N)

LR has awarded AiP certification to the 19,000 TEU LNG & battery hybrid container ship (KUN 19N) independently developed and designed by Jiangnan Shipyard.

The 19,000 TEU LNG & battery hybrid container ship is a new generation of ultra-large “Kun” series container ships independently developed by Jiangnan Shipyard. This ship utilizes Type C LNG fuel tanks, enabling dual-fuel boilers without a gas combustion unit (GCU). It also pioneers the application of a hybrid power system combining power batteries, generators, and shaft generators, optimizing and improving the energy efficiency of generators and other components, resulting in green energy saving and low carbon emissions. The stern living area and engine room are combined in a single design, while the bow bridge and fairing are integrated for energy saving and drag reduction, maximizing the ship’s container loading capacity while ensuring excellent visibility during navigation.

20,000 m³ Liquid Hydrogen Carrier

BV has granted an AiP for the 20,000 m³ liquid hydrogen carrier (Hydrogen Progress), independently developed and designed by Jiangnan Shipyard.

This vessel type is a new type of liquid hydrogen transport ship independently developed by Jiangnan Shipyard for long-distance transportation of green hydrogen in the future. It has a cargo capacity of 20,000 cubic meters and adopts a new cryogenic cargo containment system developed by Jiangnan Shipyard. Utilizing non-vacuum storage tanks, it employs an innovative design of “staged temperature control and multi-layer protection” to meet the loading requirements of liquid hydrogen at -253℃. This design effectively reduces the BOR while ensuring ship loading safety, and reduces the complexity of tank manufacturing while lowering construction costs. This vessel type is tailored for potential green hydrogen supplying countries in East Asia, the Middle East, and Australia, and will enable more flexible and economical large-scale global liquid hydrogen transportation in the future.

200,000 m³ ULAC-FSRU with Ammonia Regasification Capability (PANDA 200AF)

BV has granted an AiP for the 200,000 m³ ULAC-FSRU with ammonia regasification capability, independently developed and designed by Jiangnan Shipyard.

This vessel type is a new generation of ultra-large liquefied gas carrier independently developed by CSSC Jiangnan. Specifically designed for full-load liquid ammonia transport, it boasts a cargo capacity of 200,000 cubic meters and is equipped with an advanced ammonia regasification system. This vessel type can not only efficiently store and transport various bulk liquefied gases (such as liquid ammonia and propane), but its integrated ammonia regasification function can also meet the needs of gaseous ammonia pipeline transportation when the ship is docked, achieving efficient energy conversion from liquid to gaseous state. This innovative design makes the vessel type more adaptable and flexible in the field of liquefied gas transportation and application.

The five newly developed ship types awarded certificates at this maritime exhibition demonstrate Jiangnan Shipyard’s profound strength in ship type R&D and innovation. They also reflect the company’s consistent commitment to pioneering innovation in line with the current shipping market trend centered on high-end, green and intelligent development, its continuous achievement of new progress and breakthroughs, as well as its dedication to providing more “Jiangnan-style Chinese solutions” for the global shipping market.