On October 24, Fujian Shipbuilding Industry Group Corporation’s (Fujian Shipbuilding) Southeast Shipyard and Mawei Shipbuilding successively achieved significant milestones in shipbuilding.

On October 24, Southeast Shipyard held a naming ceremony for two 18,500 DWT oil/chemical tankers (DN517-5/6).

This vessel has an overall length of 149.8 meters and a beam of 22.8 meters. Its primary cargoes include crude oil, petroleum products with a density below 1.54 tons per cubic meter, chemicals (Classes II and III), liquid chemicals, and IMO Class II and III petroleum products listed in MARPOL Annex I and the IBC Code. The main engine and generator sets are equipped with Selective Catalytic Reduction (SCR) systems for nitrogen oxide emission control, meeting IMO Tier III requirements and ICE CLASS 1C ice-strengthened specifications.

This vessel features a multi-load line design to meet requirements of various flag states and ports. Its liquid cargo system employs six independent transfer systems driven by variable-frequency hydraulic motors, achieving a maximum liquid cargo discharge rate of 1,800 cubic meters per hour. Its propulsion system incorporates a low-speed two-stroke diesel engine paired with a controllable-pitch propeller and a forward-mounted energy-saving guide wheel assembly, complemented by a flap rudder system with a rudder ball. Additionally, it is equipped with a variable-frequency shaft generator set, enabling operation without the generator set during navigation. This configuration reduces the vessel’s energy consumption while enhancing its maneuverability.

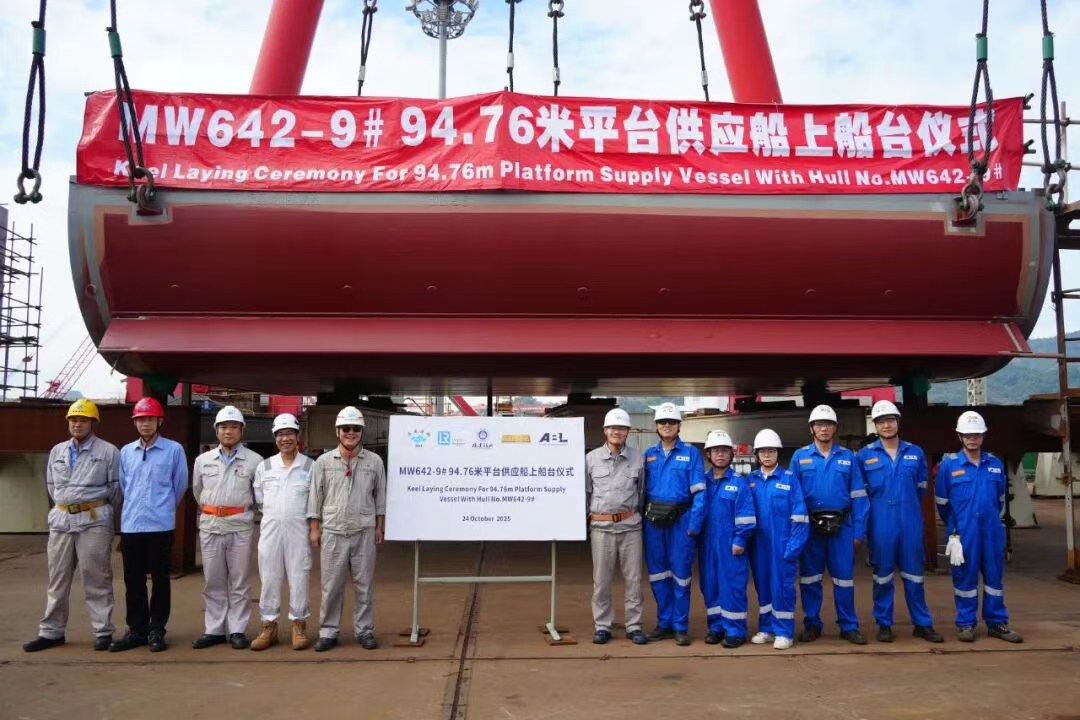

On October 24, Mawei Shipbuilding successfully laid keel for the 94.76-meter platform supply vessel (MW642-9).

The vessel has an overall length of 94.76 meters and a beam of 19 meters. It employs a new electric propulsion system powered by four 2200KW diesel generator sets, providing comprehensive power and electrical support throughout the ship. Classed by Lloyd’s Register (LR), it meets requirements for DP(AA), ECO, CAC3, and GR(ML, A) class notations.

The vessel is primarily used for the transfer of industrial personnel and materials on offshore drilling platforms. It can transport fresh water, fuel oil, cement, mud, drilling water, crude oil, methanol, materials and equipment, and can also provide firefighting and personnel rescue services for other vessels and offshore facilities. Furthermore, with provisions for future installation of ROVs/DSVs, offshore cranes, helicopter platforms, and moon pools, it is an advanced, energy-saving, environmentally friendly, electric-powered, multi-purpose platform supply vessel.