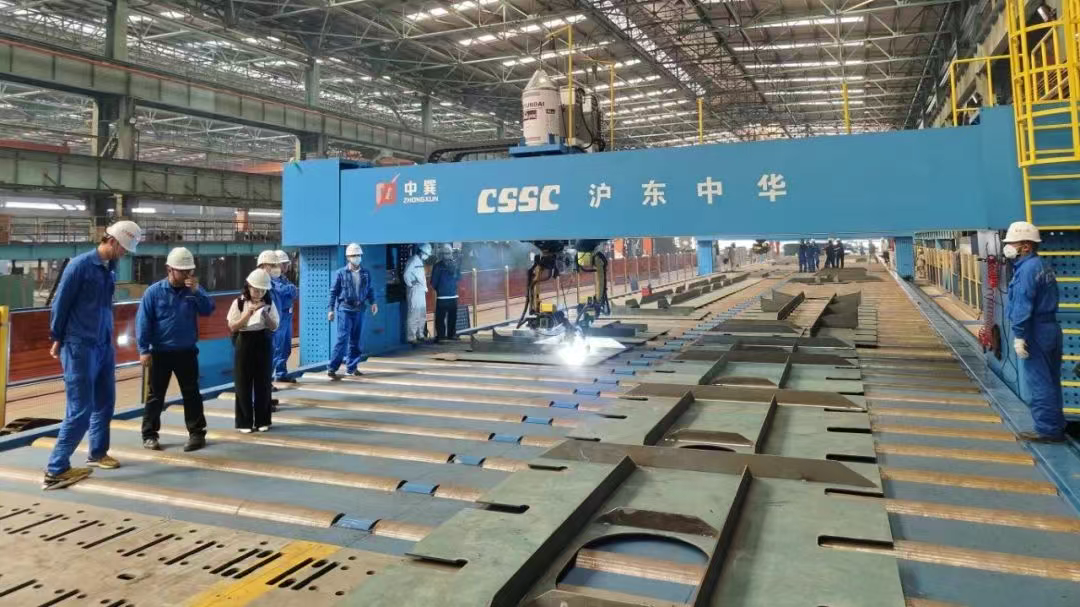

Recently, Hudong-Zhonghua Shipbuilding (Group) Co., Ltd. completed the acceptance of its component production line. As part of the LNG vessel construction capacity enhancement project, the successful acceptance of the component production line marks a solid step in the company’s intelligent upgrading, injecting strong momentum into shipbuilding.

The acceptance personnel carried out strict tests and evaluations on various performance indicators of the gantry system. The production line showed good weld quality, and the welding gantry did not experience any failures or abnormalities during long-term high-intensity production, demonstrating extremely high reliability. The AI-empowered automated welding process further exhibited high-efficiency characteristics: the robotic arms moved with precise positioning, which not only improved efficiency but also reduced errors caused by manual intervention.

The production line features a number of leading intelligent functions:

- It can automatically scan and analyze the specifications and structural parameters of various welded parts, and intelligently call parameters to complete welding.

- The operation process requires no programming, teaching, or 3D drawing import. The robot automatically matches the welding path and calls relevant parameters for welding.

- The deviation automatic compensation function can real-time monitor the operation status of the gantry. When deviations are detected, it can quickly adjust automatically to ensure welding accuracy.

- The automatic correction function detects and corrects the gantry accuracy regularly according to preset standards, keeping the gantry accuracy within 0.5mm. This precision control level is leading in the industry.

Hudong-Zhonghua stated that the production line has demonstrated remarkable welding capabilities, successfully welding over 40,000 meters of production line from trial production to acceptance. Hudong-Zhonghua will leverage this advanced gantry system to further enhance production efficiency and product quality, driving high-quality development.