Recently, Shanghai Marine Diesel Engine Research institute (SMDERI) and Beihai Shipbuilding successfully completed the delivery of the first vessel in the CAP SAN series 10600TEU container ship shaft engine retrofit project.

The vessel has been retrofitted with a 4.5MW medium-voltage shaft-driven power generation system, which is the most powerful system in the global ship retrofit market and is entirely owned by SMDERI. Once operational, the system is expected to reduce fuel costs for shipowners by approximately 8% annually and reduce carbon emissions by approximately 3,500 tons.

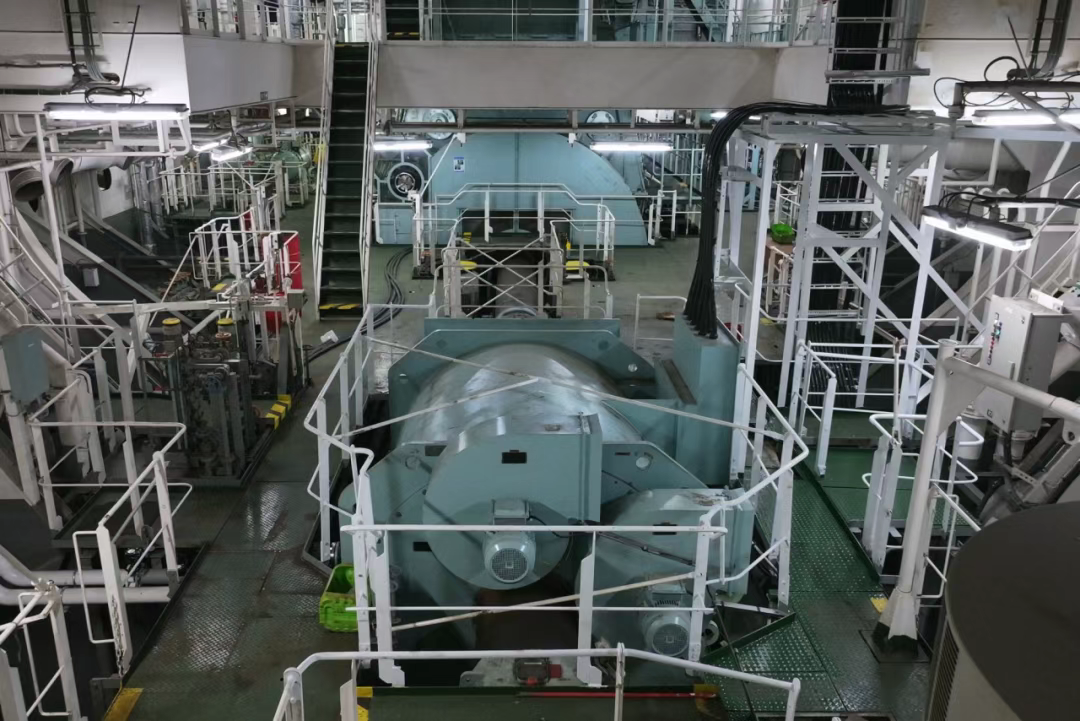

The system adopts a split-type motor structure and is designed for medium-voltage systems. It is currently the largest medium-voltage shaft drive system delivered by SMDERI and is compatible with the large ocean-going vessels of mainstream shipowners.

To ensure high-quality delivery, SMDERI conducted joint testing of the system in its own 5MW shaft generator system laboratory, completing all functional tests, including 4.5MW full load tests, load impact tests, reliability operation tests, and invited the shipowner to witness the tests on site.

The first vessel entered the shipyard on April 28, 2025. SMDERI worked efficiently with the shipowner, ship inspector and shipyard to complete the installation of equipment such as shaft generators, frequency converters, transformers, as well as medium-voltage switchboards, PMS, and AMS, and all mooring tests and inspection projects according to plan.

During the sea trials from May 27 to 30, the vessel passed all test tasks at once, and its product performance won high praise from international shipowners.

It is reported that the CAP SAN VINCENT retrofit project is an important milestone for SMDERI’s shaft generator products to enter the high-end ship renovation market, and it also once again verifies the leading advantage of SMDERI’s pioneering split-type shaft generator system solution in the field of retrofit field.