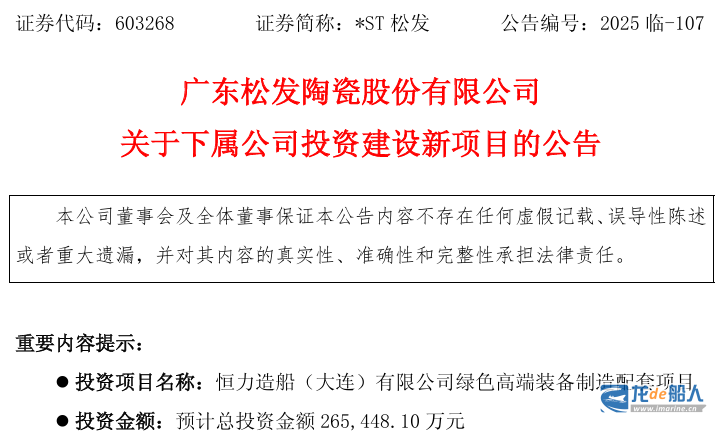

On October 18, *ST Songfa announced that its subsidiary, Hengli Shipbuilding (Dalian) Co., Ltd., plans to invest 2.654 billion yuan (approximately US$372 million) in a green, high-end equipment manufacturing project. The project will expand existing shipyard facilities by increasing large-scale steel structure workshops, auxiliary workshops, and surrounding section storage yards, among other land-based production facilities, to meet the company’s growing shipbuilding capacity demands.

*ST Songfa stated that this investment aligns with the company’s strategic planning and operational development needs, enabling the expansion and upgrading of production facilities to better meet its growing order demand. Upon completion, this project will provide an annual steel processing capacity of 400,000 tons, enabling the company to achieve production scale upgrades and cost optimization while enhancing its market competitiveness.

Based on the announcement, the project site is located within the Changxing Island Shipbuilding and Offshore Engineering Industrial Park on the northern shore of Hulushan Bay, Changxing Island, Dalian. The primary construction scope includes large-scale steel structure workshops, auxiliary workshops, supporting storage yards, and other onshore production facilities. The construction period is estimated to be approximately 12 months.

Previously reported, *ST Songfa announced plans to inject 3.932 billion yuan (approximately US$552 million) of raised funds into its wholly-owned subsidiary Hengli Heavy Industries. This includes 3.9 billion yuan paid-in registered capital and 32.05 million yuan allocated to capital reserves. Additionally, through Hengli Heavy Industries, 3.5 billion yuan of raised funds will be used to increase capital in its wholly-owned sub-subsidiary Hengli Shipbuilding (Dalian) to implement the raised-fund investment project—the Hengli Shipbuilding (Dalian) Green High-End Equipment Manufacturing Project. As of September 12, 2025, Hengli Shipbuilding’s registered capital has been increased from 6.5 billion yuan to 10 billion yuan.

Hengli Heavy Industries’ Phase I and Phase II projects are known as the “Ocean Factory” and “Future Factory,” respectively. In July 2024, Hengli Heavy Industries announced an additional investment of 9.2 billion yuan (approximately US$1.291 billion) to launch the second phase of the Hengli Heavy Industries Industrial Park, and an additional 2 billion yuan (approximately US$281 million) to build the Hengli Heavy Industries (Dalian Changxing Island) supporting industrial park. On August 15, construction began on Hengli Heavy Industries’ “Future Factory”. Just five months later, Hengli Heavy Industries’ Phase II officially began production on January 15, 2025.

The above-mentioned new projects are geographically close to Hengli Heavy Industries’ “Ocean Factory” and “Future Factory”. They focus on the development of offshore engineering, shipbuilding, conversion, high-end offshore engineering equipment and its supporting industries, marine materials, and marine components manufacturing and processing. These initiatives will accelerate Hengli Heavy Industries’ efforts to establish a world-class shipbuilding and offshore equipment manufacturing base characterized by high-end, intelligent, and green development.

Building upon its Phase I and II projects, Hengli Heavy Industries commenced construction of its Collaborative Innovation and Offshore Technology Industrial Park on September 14, 2025. To date, Hengli Heavy Industries ranks among the world’s leading large ocean-going vessel manufacturers in both its current order backlog and newly signed contracts. The company has initiated construction on over 70 vessels, with production schedules already booked through 2029. Upon full completion, the project will achieve an annual output value of 150 billion yuan. Dalian will emerge as the world’s largest single-site shipbuilding base with the most comprehensive supporting facilities.