To enhance its R&D capabilities and core competitiveness in green, high-end, and intelligent ships, Hengli Heavy Industries—an emerging private shipbuilding giant that has recently shone brightly in the industry—has announced another major move.

Investing heavily in establishing international ship research and design centers in Dalian and Shanghai

On November 11, *ST Songfa issued an announcement regarding the addition of implementation entities and locations for its fundraising projects, as well as the use of raised funds to increase capital in its wholly-owned subsidiary for project implementation.

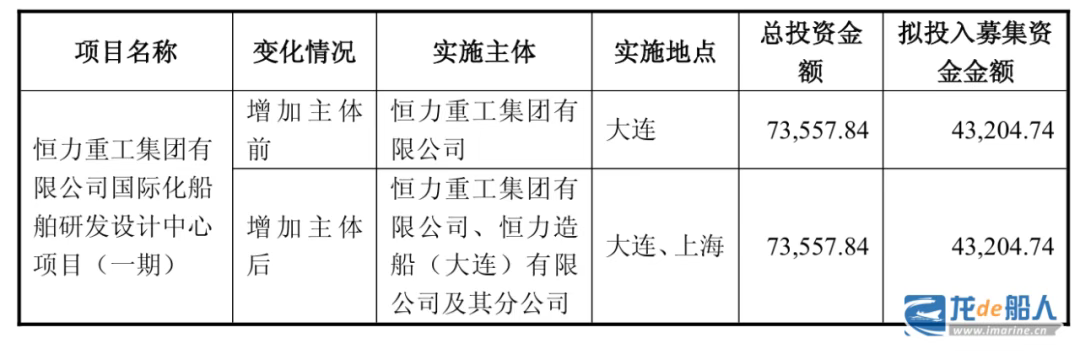

As disclosed in the announcement, *ST Songfa reviewed and approved the proposal at the 6th Meeting of the 7th Board of Directors held on November 10, 2025. The proposal agrees to add Hengli Shipbuilding (Dalian) Co., Ltd. (hereinafter referred to as “Hengli Shipbuilding”) and its branches as the implementing entities of the raised capital investment project – “Hengli Heavy Industries Group Co., Ltd. International Ship R&D and Design Center Project (Phase I)”. Meanwhile, Shanghai is added as an additional implementation location, and Hengli Heavy Industries shall use the raised funds to increase capital in Hengli Shipbuilding for the implementation of the said project.

According to the announcement, the Phase I has a total investment of 736 million yuan (approximately US$104 million), with plans to invest 432 million yuan (approximately US$61 million) in raised matching funds. Following this addition of new entities, the project implementation entities have been changed to Hengli Heavy Industries Group, Hengli Shipbuilding, and its branch (newly added). Notably, the implementation locations have been changed from the original Dalian to Dalian and Shanghai (newly added).

*ST Songfa stated that adding Hengli Shipbuilding and its subsidiaries as implementing entities for the fundraising investment projects will fully leverage their R&D team strengths, optimize the company’s resource allocation, enhance overall operational efficiency, accelerate project implementation progress, improve the efficiency of raised funds utilization, and align with the company’s actual needs.

*ST Songfa further emphasized that Shanghai, as a world-class shipping center, not only possesses leading international shipping resources and international market reach, but also boasts a leading international pool of design talent in ship design, shipbuilding, and offshore engineering equipment. Shanghai is home to numerous internationally renowned ship design institutes and national-level research institutions, resulting in a particularly strong concentration of high-end ship R&D and design talent.

The addition of Shanghai as the implementation location for the fundraising project is intended to leverage the unique locational advantages of the Shanghai International Shipping Center to further strengthen the R&D team, build a world-class R&D platform, continuously attract top global talent, and ultimately enhance the company’s R&D capabilities and core competitiveness in green, high-end, and intelligent ships.

New outfitting pier construction, capital increase of $282 million

In addition to the aforementioned issue, *ST Songfa recently released two other important announcements concerning capital increases and the construction of new infrastructure.

Specifically, Hengli Offshore Engineering, a subsidiary of *ST Songfa, plans to invest in the construction of a outfitting pier project. The total investment is estimated at 458 million yuan (approximately US$64 million), with a construction period of about 12 months. Located in the eastern pier area of the southern shore within the Changxing Island Port Zone, the project’s main components include the outfitting pier, two crane installations, two boarding towers, public utilities, and supporting infrastructure.

This initiative aims to address the company’s growing demand for large-vessel berthing and outfitting capabilities. Upon completion, the project will be able to accommodate outfitting operations for vessels ranging from 100,000 to 400,000 tons, and will be able to undertake the construction of large marine engineering equipment such as high-end ships, offshore drilling platforms, and offshore wind power installation vessels, significantly enhancing its shipbuilding and outfitting capabilities. It will also further improve the supporting service capabilities for shipbuilding and marine engineering equipment manufacturing, promoting the development of the shipbuilding and marine engineering equipment industry towards refinement and specialization.

Another significant announcement disclosed that Hengli Heavy Industries plans to inject 2 billion yuan (approximately US$282 million) in capital into Hengli Shipbuilding using its own funds and internally raised capital. Upon completion of this capital increase, Hengli Shipbuilding’s registered capital will rise from 10 billion yuan to 12 billion yuan (approximately US$1.69 billion).

This move aims to meet the funding needs of Hengli Shipbuilding’s daily production and business development. The increased capital will be mainly used to supplement the working capital required for Hengli Shipbuilding’s daily operations and the capital gap for the green high-end equipment manufacturing project, thereby further enhancing Hengli Shipbuilding’s financial strength and operational capabilities and helping to accelerate the implementation of the green high-end equipment manufacturing project.

According to Clarksons data, in 2024, Hengli Heavy Industries ranked among the world’s top ten shipyards, securing the fourth position with 56 vessels and 2.68 million CGT in new orders. This year, Hengli Heavy Industries continues to ignite the global newbuilding market and achieve impressive performance.

To date, Hengli Heavy Industries ranks among the world’s leading large ocean-going ship manufacturers in terms of both its current order backlog and newly secured orders. The company has commenced construction on over 70 vessels, with production schedules already booked through 2029.