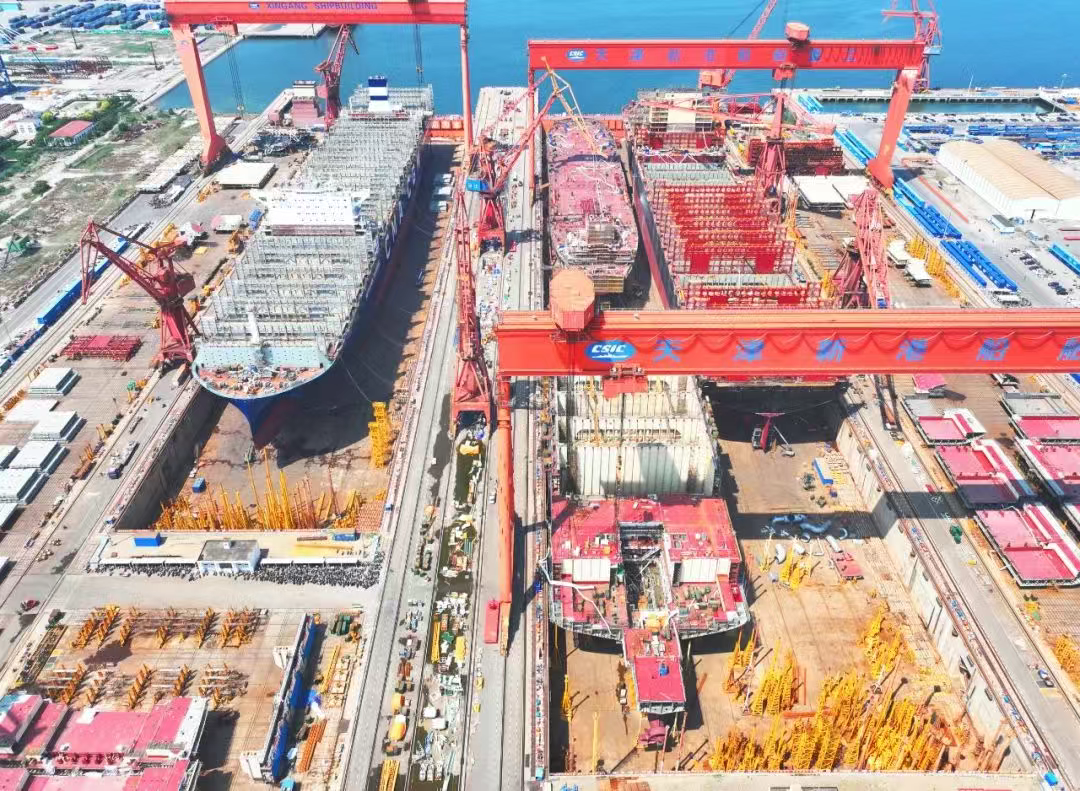

Recently, four large ships were being built simultaneously at CSSC (Tianjin) Shipbuilding under Dalian Shipbuilding Industry Corporation (DSIC), marking a critical stage for the full release of production capacity at CSSC (Tianjin) Shipbuilding.

In Dock No. 1, the C16K-15 LNG dual-fuel container ship, the C16K-17 methanol dual-fuel container ship and the first P110K-84 product oil tanker formed an impressive “three ships under construction” layout.

Faced with the technical challenges of the C16K-15 ship, CSSC (Tianjin) Shipbuilding achieved a major breakthrough based on the experience of previous ships. For the first time, it independently used a three-dimensional adjustment instrument to complete the adjustment of the B-type LNG tank, saving a lot of fees for external service providers and consolidating the core technology of LNG fuel tank installation.

The C16K-17 methanol dual-fuel ship is currently under construction. The construction team innovatively adopted a “planning-first” model and established a coordination mechanism with the shipowner and ship inspection agency to identify multiple technical difficulties in advance and formulate solutions, thereby successfully avoiding risks.

The General Assembly Manufacturing Department of CSSC (Tianjin) Shipbuilding has established a management system of “technical briefing-process monitoring-acceptance closed loop” with cooperative units for high-risk processes such as scaffolding erection of the P110K – 84 product oil tanker to ensure the safe and orderly construction of subsequent operations.

In Dock No. 2, the C16K-16 methanol dual-fuel container ship is the first ship built by CSSC (Tianjin) Shipbuilding for CMA CGM. During the keel-laying stage, a “full-process risk deduction” was carried out to verify issues related to water depth engineering equipment and its accessories, as well as the outfitting integrity of the methanol tanks one by one. By driving the collaborative advancement of production departments and production auxiliary departments in reverse through a backcasting plan, the special coating cycle of the methanol tanks was effectively shortened.

To date, CSSC (Tianjin) Shipbuilding has completed all production milestones in accordance with its annual plan.

At present, CSSC (Tianjin) Shipbuilding is operating at full speed in an efficient mode of “dual dock linkage and three parallel production lines”. From design and development to final assembly and manufacturing, from equipment commissioning to sea trial preparation, all links in the entire industry chain are seamlessly connected, quality is controlled with “millimeter-level” precision, production is promoted with “minute-level” efficiency, and the record of green shipbuilding is continuously refreshed.