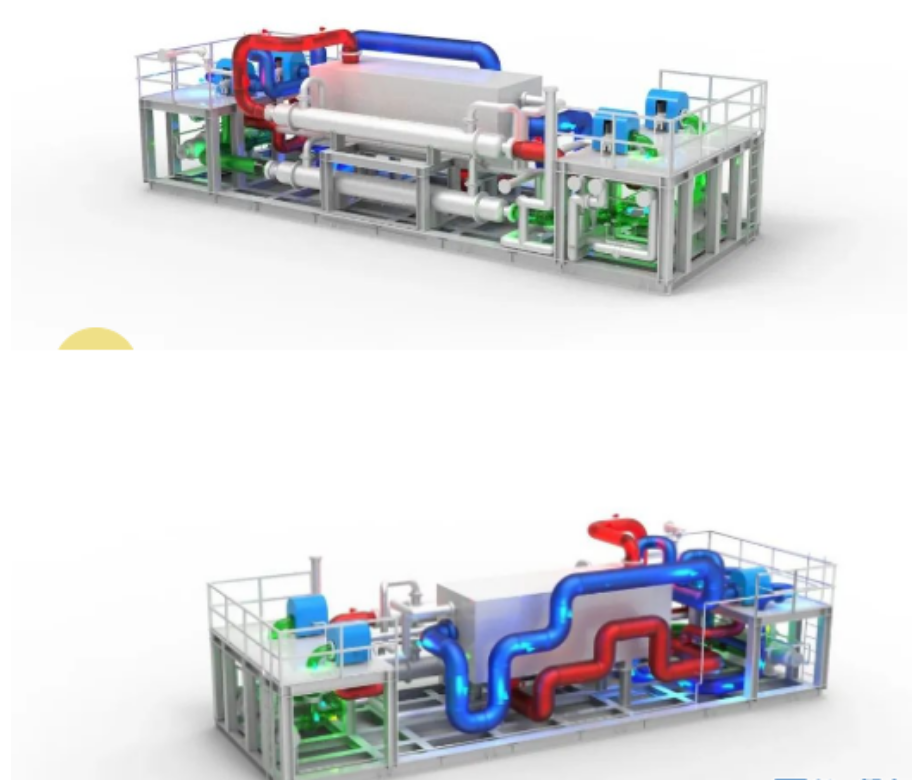

Recently, Shanghai Qiyao Environmental Protection Technology Co., Ltd, a subsidiary of Shanghai Marine Diesel Engine Research institute (SMDERI), independently developed the first set of LNG deep-cooling re-liquefaction plant (LSC1000) in China, successfully completed the system function and performance test, and successfully passed the FAT acceptance.

In order to respond to the urgent demand for the independent control of key equipments for China’s offshore LNG carriers, Qiyao Environmental Protection Technology has completed the independent development of LNG deep-cooling re-liquefaction plant by overcoming the multiple difficulties such as tight development cycle, severe space size limitation, technical difficulties of core components and lacking of experience in real ship applications from the design of the process principle to the development of the core equipments and the overall integration of the system.

This device is the first set of high-efficiency marine LNG evaporated gas (BOG) re-liquefaction device based on the LNG deep-cooling technology route with fully independent intellectual property rights in China. The device realizes the re-balanced liquefaction of BOG by making use of the cold energy generated by the compression and expansion of nitrogen and helium to deep-cool the LNG and then spray it back to the tanks, which not only avoids the economic losses and greenhouse hazards caused by the direct combustion and emission of BOG, but also ensures that the temperature and pressure inside the cargo tanks are in an appropriate range, thus reducing the generation of BOG from the source, and it has the advantages of being stable, efficient, safe and reliable, and free of maintenance for a long period of time.