On December 2, 2025, a handover ceremony was held for the Phase II coating workshop at the new shipbuilding facility of Hudong-Zhonghua Shipbuilding, a subsidiary of China State Shipbuilding Corporation. The project had commenced construction on January 22 of the same year.

Hudong-Zhonghua Shipbuilding stated that the newly constructed coating workshop complies with environmental and safety standards for the ship coating industry. Equipped with various advanced coating facilities and enabling real-time data exchange, it effectively addresses pain points inherent in traditional construction models, such as inefficient process coordination and inadequate adaptability.

According to reports, the project has faced multiple construction challenges since its launch. The project team spent nearly six months focusing on the core difficulties of engineering construction, optimized plans through repeated discussions, and adopted targeted measures to break through technical bottlenecks. They successfully overcame several key challenges, including millimeter-level precision control, efficient coordination of multi-disciplinary cross-operation, and the dynamic balance between “compliant design and production adaptability”. Ultimately, all construction tasks of the coating workshop were completed on schedule with high quality and passed the completion acceptance smoothly.

Hudong-Zhonghua Shipbuilding announced that the completion of the painting workshop (Phase II project) at its new facility marks the full realization of the capacity expansion project for Phase II of the CSSC Changxing Shipbuilding Base. Phase II of the CSSC Changxing Shipbuilding Base—namely, the new Hudong-Zhonghua’s new facility—officially commenced operation on May 19, 2025.

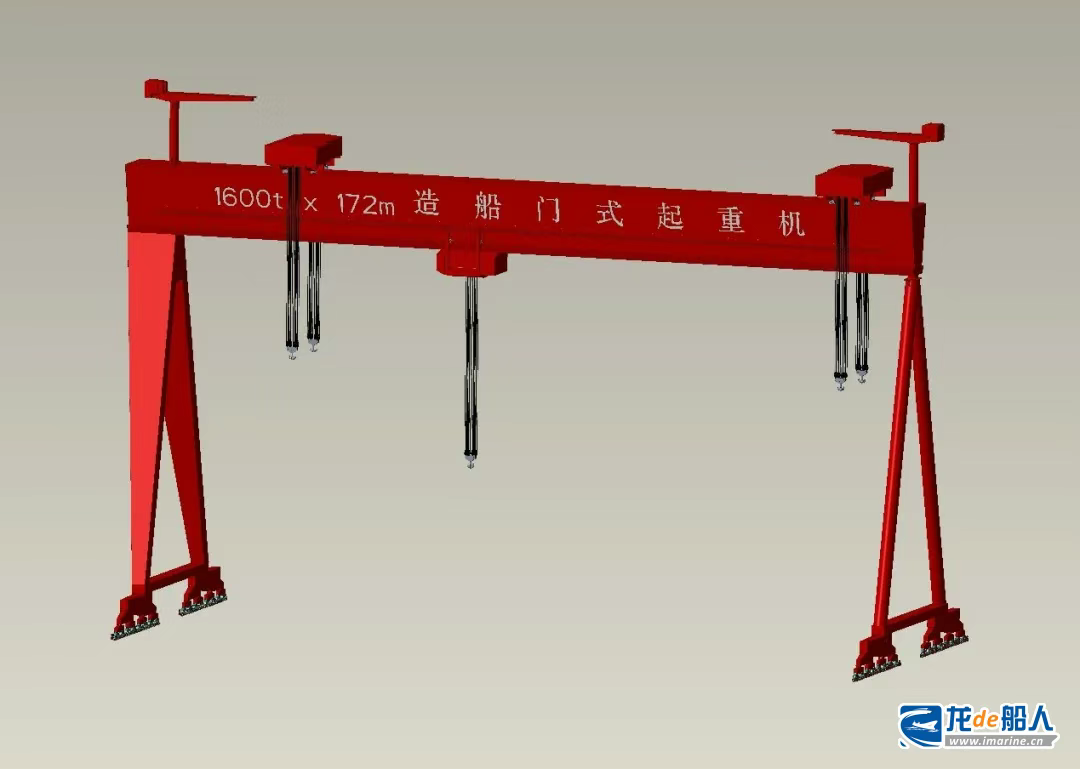

In the months following the launch of its new facility, Hudong-Zhonghua Shipbuilding is accelerating efforts to boost shipbuilding capacity. Projects including the construction of a new 1,600-ton gantry crane for Dock No. 1 and the extension and renovation of Dock No. 2 have been successively initiated.

On August 5, 2025, construction commenced on Hudong-Zhonghua’s 1,600-ton shipbuilding gantry crane. With a total weight of approximately 3,500 tons and a rated lifting capacity of 1,600 tons, this gantry crane features a single-girder structure spanning 172 meters. Its lightweight design enables efficient assembly of ship blocks, providing functions including lifting, hoisting, aerial section rotation, and horizontal micro-rotation.

This gantry crane will be installed at Dock No. 1 of Hudong-Zhonghua Shipbuilding’s Changxing Base. It represents the largest-tonnage gantry crane designed and manufactured by CSSC Ninth Design & Research Institute(CSSC NDRI) at the time, and will also become a landmark “giant” at Hudong-Zhonghua’s Changxing shipbuilding base.

In addition to the crane project, the preliminary design for the extension and renovation of Dock No. 2 at the Phase II project of the CSSC Changxing Shipbuilding Base is also being undertaken by CSSC NDRI. The total investment of the project is approximately RMB 390 million, with a total new building area of 324 square meters and 5 sets of new (renovated) process equipment added. The project involves the reconstruction of the dock with a tonnage of more than 10,000 tons.

The main construction contents of the project include: extending Dock No. 2 by 220 meters toward the land area to a total length of 660 meters, and constructing stern and side block assembly yards with a total area of 27,180 square meters; extending the rails of the 700-ton gantry crane and the portal cranes on both sides of the dock by 223 meters and 240 meters respectively.

Public information indicates that Hudong-Zhonghua’s new facility is located along the southern coast of Changxing Island in Shanghai, covering a total construction area of 431.8 hectares and with a planned investment of RMB 18 billion (approximately US$2.507 billion).

The first phase of construction will cover 214.6 hectares, with a planned investment of RMB 8 billion (approximately US$11.14 billion). Construction projects primarily include a research and design building, a hull joint workshop, a curved block assembly and welding workshop, an outfitting module center, a coating shop, indoor dock No. 1, outdoor dock No. 2, a harbor basin and an outfitting pier. With a planned construction area of 460,000 square meters, the project will have an annual production capacity of ten special vessels.

Notably, in the large LNG carrier market, Hudong-Zhonghua Shipbuilding secured orders for up to six 174,000 m³ LNG carriers this year. The shipowner is Bonny Gas Transport, a shipping subsidiary of Nigeria LNG Limited (NLNG). This marks the shipyard’s first newbuilding order in the LNG carrier market this year and represents China’s first LNG carrier order secured for 2025.

As one of China’s earliest shipyards to build large LNG carriers, Hudong-Zhonghua Shipbuilding has recently achieved another significant breakthrough in the LNG carrier construction market.

On December 3, the LNG carrier (hull number: H1893A) constructed by Hudong-Zhonghua Shipbuilding completed its sea trials. The vessel integrates multiple domestically produced first-of-a-kind core LNG equipment, covering key systems including propulsion, storage and transportation, environmental protection, and materials. During sea trials, targeted specialized tests were conducted. All domestically produced equipment withstood complex sea conditions, demonstrating stable operation with key performance metrics exceeding expectations. This marks a leap forward in China’s localization of core LNG carrier equipment.